Smart Maintenance Operations: from preventive maintenance to predictive maintenance

According to a study conducted jointly by KPMG and L’Usine Nouvelle, two-thirds of the companies surveyed consider the increasing availability of equipment in factories to be a top priority over cost reduction and quality improvement. In fact, plant downtime can be very costly — ranging from $10,000 to $50,000 per minute — depending on the industry (e.g. $22,000 for the automotive industry). However, wrench time in factories has remained stable for almost a decade, demonstrating a real gap between the need for productivity and maintenance efficiency.

In the past, maintenance services were mainly corrective and preventive, meaning that equipment was repaired in the event of an immediate failure or default, or that preventive maintenance operations were scheduled based on time and usage parameters. This maintenance management was based solely on the assumption that the equipment would be degraded after a certain period of time.

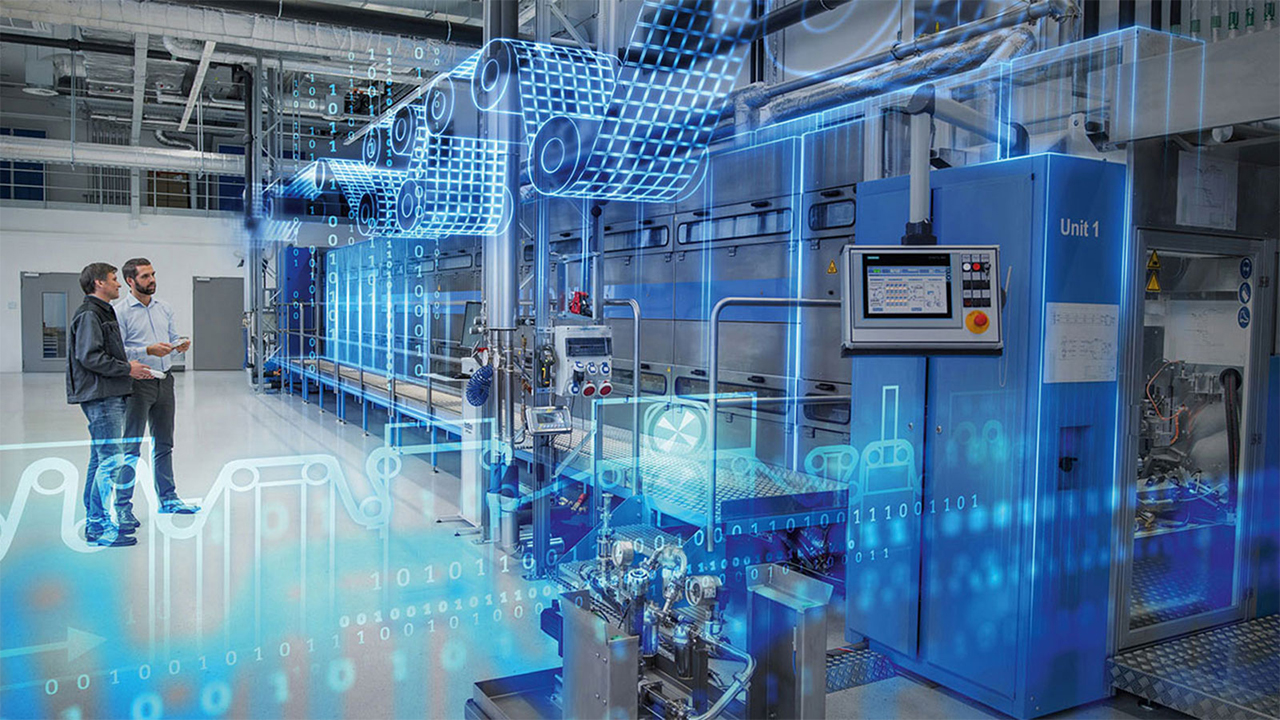

Over the past two decades, the adoption of digital technologies has paved the way for smart maintenance. In particular, advances in data management have made it possible to shift from preventive to condition-based maintenance. Condition-based maintenance monitors the condition of an asset in real-time to determine when a parameter reaches an unsatisfactory level in order to plan a maintenance intervention.

More recently, the ongoing transformation of manufacturing practices, driven by machine learning, artificial intelligence and automation, has led to the rise of Smart Maintenance in factories. Several startups are now positioning themselves on this market and developing innovative solutions to optimize and facilitate maintenance operations, based on 3 main pillars:

- Asset monitoring and geolocation, which uses data analysis to provide real-time visibility on the location and condition of the materials and assets within the supply chain. As part of asset monitoring, predictive maintenance allows to accurately predict when a component will fail and determine when to repair it, reducing downtime costs. It often involves the creation of a Digital Twin, a digital replica of a physical asset, developed to replicate the original behavior model.

- Reverse engineering and 3D scanning technologies, which uses data to create 3D virtual models for Computer Aided Manufacturing and Computer Aided Design softwares. These models can be used as a complement to virtual and augmented reality to train workers to maintenance operations.

- Blue Collar Empowering technologies, such as voice recognition, instruction digitalization and project management softwares, which improve worker performance. These technologies are efficient assistants because they save maintenance workers from typing their maintenance or reading complex manuals.

In conclusion, Smart Maintenance has become crucial to maximize uptime and reduce production costs, but also to extend equipment lifetime, ensure compliance and enhance security and energy consumption. However, manufacturing companies may be a little reluctant given the significant investment involved in the transition to Smart Maintenance, especially in this time of crisis. Smart maintenance operations also addresses the critical need for energy optimisation. In France, 20% of energy savings in the industrial sector can still be easily achieved through smarter equipment. Aster Fab is committed to the energy transition in the industrial sector through the INVEEST Programme, an initiative that supports financial and industrial professionals in their transformation. Please contact us to learn more.

2 Key Figures

135 Digital Twin startups

are focusing on developing solutions for the Logistics, Supply Chain, and Maintenance sectors

Market size expected to reach $12.3bn by 2025

According to Markets & Markets, the global predictive maintenance market was valued at $4bn in 2019 and is expected to reach $12.3bn by 2025.

3 startups to draw inspiration from

This week, we identified three startups that we can draw inspiration from: Falkonry, Polyga, and Datch Systems.

Falkonry

Falkonry is a US-based startup offering a ready-to-use machine learning system that helps companies improve their industrial operations in terms of performance, throughput, quality and yield.

Polyga

Polyga is a Canadian startup developing 3D scanners and a mesh processing software to facilitate the use of scan data within Computer Aided Design and Computer Aided Manufacturing systems.

Datch Systems

Based in the UK, Datch Systems develops an intelligent voice interface for industry, enabling blue workers to use their voice to document their work.

123Fab #11

1 topic, 2 key figures, 3 startups to draw inspiration from

How can battery innovation power the rise of electromobility?

The need to tackle global warming and improve air quality has led to an exponential increase in the use of Electric Vehicles (EV). Electromobility has been a crucial topic for governments and automotive manufacturers, and regulation incentives have contributed to accelerate the transition to EV. According to Forbes, there were 7.2 million electric cars on the road worldwide in 2019, up from 17,000 in 2010. The growing EV adoption implies an increase in EV production, which translates into an increase in battery production.

However, the growing number of EV and batteries being produced brings with it a new set of challenges: uncertainty about battery range and charging times, electric grid imbalance and a shortage of raw materials, especially lithium, which is the scarce material used in battery production.

Consequently, battery innovation is crucial to disrupt electromobility and battery startups and manufacturers are working to improve the performance, durability, optimisation and recycling of batteries.

- Lithium-ion technology dominates electromobility use cases, and will dominate for at least the next 20 years, but alternatives are being developed such as sodium-ion, lithium-sulfur or lithium-air. These alternatives allow to either replace lithium, generate higher capacity and longer lifetime or create safer batteries. Innovation is also underway in the structure of batteries, from cell structure to modules and packs, allowing to save space, optimize charging time and control the temperature.

- EV Li-ion batteries need to be cooled because excessive temperatures can cause capacity degradation, thermal runaway or fire explosion. Some startups and Original Equipment Manufacturers (OEM) are focusing on developing Thermal Management Systems (TMS) to cool them.

- Startups and corporates are also testing and offering software and analytical solutions that have a signficant impact on the battery lifecycle by improving its development, optimizing its operations and solving reinsurance issues.

- Finally, startups and OEM are exploring three emerging business models:

- Battery leasing, which is discontinued by OEM as battery prices fall;

- Battery swapping, which is mainly used by micromobility operators;

- Battery recycling, which allows old EV batteries to be reused for stationary storage.

In conclusion, battery innovation is evolving very rapidly, both in terms of technologies and business models and is making a major contribution to the rise of electromobility by making EV more efficient and resilient. The market is still young and needs more structure, as a large number of corporates and startups are positioning themselves on the battery value chain. In particular, OEMs have developed Open Innovation strategies through M&A or strategic investments to acquire upstream battery competences and technologies. It is hoped that the Covid-19 pandemic will accelerate research and investment in this sector to ensure a rapid and effective transition to electric vehicles.

2 Key Figures

Battery storage startups raised $1.7bn in 2019

According to Business Insider, battery storage startups raised $1.7bn in 2019 of which $1.4bn were raised by Li-ion battery startups.

Market size expected to reach $84bn by 2025

According to PR Newswire, the global Electric Vehicle battery market size was valued at $23bn in 2017 and is expected to reach $84bn by 2025.

3 startups to draw inspiration from

This week, we identified three startups that we can draw inspiration from: Tiamat, Feasible and Relectrify.

Tiamat

Tiamat is a French startup that designs, develops, and manufactures sodium-ion batteries for mobility and stationary storage.

Feasible

Based in the US, Feasible develops the EchoStat Platform, which delivers unique real-time insights on the battery, by using ultrasounds to detect physical properties of batteries.

Relectrify

Relectrify is an Australia-based startup making energy storage affordable by unlocking full performance from battery cells in order to increase battery cycle life.

123Fab #10

1 topic, 2 key figures, 3 startups to draw inspiration from

How to effectively manage large projects in the digital era

Over the past two decades, companies and industries have had to deal with unprecedented and accelerating dynamics. The rise of digital technologies and the Internet has brought about radical changes for organizations, forcing them to adapt slowly and transform their working methods and tools into a new digital fluid space for communication, creation, information processing and knowledge sharing. The COVID-19 pandemic has emphasized and accelerated this digital transition.

Digital transformation has fundamentally changed the way large companies and industries manage their projects, sustain their knowledge base and deliver value to their customers. Fully embracing the integration of web-based technologies, traditional project management has been replaced by a more digital and agile generation known as project management 2.0 (PM2).

Project management 2.0 implies the adoption and use of IT tools to monitor a large array of aspects of large complex projects to increase team performance, gain a more complete view of the project and ensure its success. In particular, data management processes, integrated with project management softwares, have been a real game changer to maximize project productivity and time management.

Digital technologies have helped redefine a more efficient approach to project management, through the development of strategic software. Key softwares for PM2 are:

- Collaborative communication tools: the use of collaborative work environment software enables a more effective cross-team communication and coordination by allowing all team members to connect, interact and organize their work while tracking the project progress in real-time.

- Document management softwares, allowing team members and co-workers to share documents on the cloud to ensure that all participants have the same level of knowledge, develop collective intelligence and capitalize on their expertise.

- Computer Aided Design and Computer Aided Manufacturing, which enables virtual models to be designed, optimized and tested while sharing information with team members. This type of software improves communication throughout the modelling process, but also to creates a useful database for manufacturing.

- Automated project management softwares, powered by artificial intelligence, use all the data generated during the project to improve planning, predictive scheduling and cost management, because managing time, resources and progress is key to get the best outcomes.

- Safety and Risk Management softwares, which also use artificial intelligence to prevent and manage risks during the project.

These analytical technologies allow project managers to have time to focus on strategy optimization and project delivery rather than on project processes and coordination.

Consequently, project management softwares are becoming crucial and strategic tools for businesses and industries, which explains the increase of innovative players on the market, both in terms of technology and business models. The market is very dense due to the presence of many startups and large corporations, but emerging startups are making their mark by developing innovative technologies and striving to become more engaged with customer while optimizing the project management processes.

2 Key Figures

97 project management startups

received early-stage in the past two years

Market size expected to reach $6.7bn by 2026

According to GlobeNewswire, Global online project management software market is expected to reach $6.68bn by 2026, due to the increasing adoption of cloud-based solutions.

3 startups to draw inspiration from

This week, we identified three startups that we can draw inspiration from: Wizzcad, Sharktower AI and Sitetracker.

Wizzcad

Wizzcad is a French startup providing a BIM (Building Information Modeling) based SaaS platform for digital transformation of construction projects, from design to operations and maintenance.

Sharktower AI

Sharktower AI is a UK-based startup developing a data and AI software to transform how businesses deliver change by providing portfolio insights visualization, predictive analytics and decision-making without bias.

Sitetracker

Sitetracker is a US startup which raised $10 million to develop a cloud-based project management platform that powers successful deployment of critical infrastructure.

123Fab #9

1 topic, 2 key figures, 3 startups to draw inspiration from

Cybersecurity in the time of the COVID-19 pandemic

Before the COVID-19 outbreak, cyber threats were already increasing exponentially — expected to reach 4 million threat types by 2025, according to ITU News. But the global pandemic has catalyzed the creation of an ideal environment for cybercriminals, taking advantage of the less secure wireless networks in use and the chaos and anxiety associated with the pandemic.

Cyber attacks have reached unprecedented levels with almost 1M phishing and website scams registered by Google during the first three months of 2020 alone. And big tech companies, hospitals, international and national organizations, including the World Health Organization, the United Nations and NASA, were massively targeted by ransomware attacks during the pandemic, with a spike of 300% additional phishing and malware attacks across their network infrastructures.

Breach attempts are increasingly sophisticated and complex, which raises many questions about security and privacy issues in the highly connected environment we live in. Cybersecurity investments are rising each year, reaching $10bn invested in privacy and security companies in 2019, compared to $1.7bn in 2010, according to a recent Crunchbase query.

In order to better resist cybercriminal attacks, startups are developing specific technologies: biometrics with fingerprint and facial recognition to ensure strong authentication, encryption 2.0 to secure data and storage, automated testing to ensure the security of software and operating systems and artificial intelligence to detect and prevent the risk of cyber attacks. With the rise of these new protection and security technologies, related business models are emerging, such as Encryption-as-a-service, Authentication-as-a-service, Assessment-as-a-service and even white hackers to test the vulnerability of your system.

2 Key Figures

1,1653 cybersecurity startups

received seed funding in the last twelve months

Market size worth $1.5tn in 2018

In 2018, the cybercrime economy was estimated to be worth $1.5 trillion, according to a study commissioned by Bromium.

3 startups to draw inspiration from

This week, we identified three startups that we can draw inspiration from: Senseon, Zero Networks and Semperis.

Senseon

Based in London, Senseon is a self-driving cyber defense platform using artificial intelligence in order to detect, investigate and respond to cyber threats. The startup has raised €5.8 million in February 2019.

Zero Networks

Zero Networks is an Israeli-based startup focusing on automating the development and enforcement of network access rules throughout an entire network.

Semperis

Semperis is a US-based startup developing enterprise identity protection and cyber resilience that enables companies to quickly recover from accidental and malicious damages on cloud or hybrid environments.

123Fab #7

1 topic, 2 key figures, 3 startups to draw inspiration from

While a large portion of the working population is being asked to work from home when they can, the need for remote simulation and monitoring has increased dramatically. This has led us to address the increasingly relevant topic of ‘Digital Twins’, or how the combination of connected sensors, digital modeling and artificial intelligence work together to serve Industry 4.0. It is especially useful for remote operations: NASA was the first to really leverage twin technology to ensure the maintenance of its assets, thousands of kilometers away.

Digital Twins (DT) are a virtual representation of physical assets or networks. It is composed of three main elements:

- A physical part: the product, component, process or network to be twinned

- Its virtual replica: including the physical and chemical specificities of each material or component

- Data flow: coming from the connected physical product and enriching the virtual replica in real time, providing risk and performance information.

Digital Twins are therefore very different from a digital model since you start from the physical product to build its twin, and not the other way around. The idea of dynamics, of movement, is also crucial to understand the depth of DT and the variety of use cases.

In its most static form, DT transcribes real-time data from a physical asset, which facilitates testing and maintenance. Continuous data collection provides a thorough history of the physical asset’s performance and problems, and this data can feed machine learning algorithms to draw the line further into the future and improve their predictive capability. The so-called Predictive Twin is an extension of the original DT as it allows the execution of what-if scenarios. This allows you to save money by investing better (you can test a new product or a new part of your asset and see if it performs according to plan) and to support your operating decisions (for example, when operating a power grid, you can run a scenario on how the grid will behave if you shut down a generator, increase your renewable energy consumption, or experience a large increase in demand).

The main sectors interested in Digital Twins are Manufacturing, complex Engineering (aerospace, automotive, railway…), Health, Energy, but also network operations (grid operators, logistics and supply chain). Chevron, for example, expressed the ambition to save millions a year thanks to digital twins.

However, the deployment of Digital Twins is slowed down by a series of technical and organisational complexities:

- From a technical point of view, the very creation of the virtual replica is highly sensitive and has a significant impact on product performance because you need to create a data transfer system which wasn’t necessary before. Building a realistic replica also requires, on the one hand, powerful modeling technologies and, on the other hand, a fairly cross-disciplinary approach to feed physics and chemistry (for components’ specs and behavior), product engineering, manufacturing operations or in-field environment data

- Once created, the virtual replica must fit somewhere in the existing IT environment: how is it connected to existing ERPs? To what extent is the approach standardized, especially if the company has different DT?

- By centralising access to the virtual replica, DT also raise the question of ownership and decision-making. Who operates the DT? How does it connect to field teams? Who is responsible in the event of a real problem?

Digital Twins combine the best of several technologies into a single solution with a proven ability to generate commercial impact. However, performance varies greatly depending on the company’s digital know-how: because DT work best when deeply integrated into the different stages of the organization – from prototyping to predictive maintenance – its performance and ROI in isolated projects is lower than when it is established at the group level for multiple projects.

2 Key Figures

53 digital twin startups

listed worldwide (created after 2005)

Market size expected to reach $26.1bn by 2025

According to a report carried out by Grand View Research, Inc., the global twin market is projected to be worth $26.07 billion by 2025, registering a CAGR of 38.2% during the period 2019-2025.

3 startups to draw inspiration from

This week, we identified three startups that we can draw inspiration from: Akselos, SightMachine, TWAICE.

Akselos

The Swiss company specializes in Digital Twins for large-scale assets and infrastructure and is already present in 5 locations worldwide.

SightMachine

The US company specializes in upstream digital twins, namely for manufacturing operations, and combines production processes and product data for a better productivity.

TWAICE

The German company empowers electric mobility by providing digital twin technology for batteries. By better predicting the aging and performance of the cells, Twaice improves the reliability of battery systems.

123Fab #6

1 topic, 2 key figures, 3 startups to draw inspiration from

Going “contactless” is kind of trendy right now, and we didn’t want to miss out on industry awareness.

Non-destructive testing (NDT) has been around for some time and covers a wide range of underlying technologies. By allowing the examination or evaluation of an asset (materials, parts, assembly, etc.) without altering or even touching it, NDT detects conditions or discontinuities that may or may not impact the integrity of an asset and is therefore used for both in-field inspection and in-line manufacturing quality control. The main application sectors for NDT are Energy (nuclear, oil and gas, power generation), Aerospace, Construction, Automotive and Medical. The technologies enabling NDT range from a very low technology approach (visual inspection) to various methods of computer-aided perception: magnetic particle, liquid penetrant, eddy current, acoustic emission, ultrasonic…

While some major incumbent operators are well established (Mistras, Olympus, General Electric…), startups are increasingly challenging the market with new technologies such as AI-empowered computer vision (even from standard devices) or Terahertz. The former remains useful for surface inspection and can very quickly assess and categorize defaults. As the hardware is not the most important part of the tool, the cameras can be integrated on different supports (ground robots, drones, wearables) and allow easy data acquisition. The latter is dedicated to seeing through coatings, metallic surfaces and inside dielectric materials (such as plastics and composites) to inspect various layers and is used to assess production mistakes such as abnormalities from foreign material inclusions, disbond and delamination or heat damage for instance. As terahertz is non-ionizing, new applications in the food industry are also being tested.

NDT is particularly relevant for industry as it achieves 3 main objectives:

- Operational and environmental performance: when used on a production line, NDT makes it possible to test a greater number of parts, thus reducing the volume of waste in the event of a defect identified in a production batch. In the automotive parts industry, for example, instead of testing 1 part out of 100 of a composite component (it is necessary to regularly break down a product to look for assembly defects), NDT allows each unit to be scanned at the end of the line and the integrity of the components to be guaranteed.

- More uptime: when used on site, NDT systems do not interrupt operations and allow maintenance and inspection to be carried out without altering production capacity.

- Compliance & safety: NDT meets the needs of a safer and more reliable workplace by allowing a thorough and regular assessment of assets, thus increasing machine reliability. It is also a strong ally for compliance – insurance companies, for example, find use cases for car damage expertise using computer vision analysis.

However, contactless inspection does not mean that it is free of human interaction. Inspectors still have a crucial role to play in NDT, both in the acquisition and evaluation of NDT data, and are therefore subject to human error. One of the key challenges in NDT is therefore to improve the replicability of measurements and to smooth out the human factor.

2 Key Figures

94 non-destructive testing startups

listed worldwide (created after 2005)

Market size expected to reach $30,312bn by 2025

According to PR Newswire, the global non-destructive testing equipment market was valued at USD 14,099.26 million in 2019, and is projected to be worth $30,312.98 billion by 2025, registering a CAGR of 6% during the period 2020-2025.

3 startups to draw inspiration from

This week, we identified three startups that we can draw inspiration from: Novosound, Lynx Inspection and Teratonics.

Novosound

Novosound is a Scottish startup specialized in ultrasound sensors. The company focuses on Oil & Gas, Aerospace, Nuclear and Medical.

Lynx Inspection

The Canadian company focuses on X-ray imagery with computer vision. Defaults are found and analyzed by comparing features in the X-ray images with the expected results from a corresponding sequence of simulated images. The company positions itself as a cheaper and faster alternative to computed tomography.

Teratonics

Teratonics is a French company offering Terahertz analysis. The company focuses on the automotive, aerospace and energy sectors.

123Fab #5

1 topic, 2 key figures, 3 startups to draw inspiration from

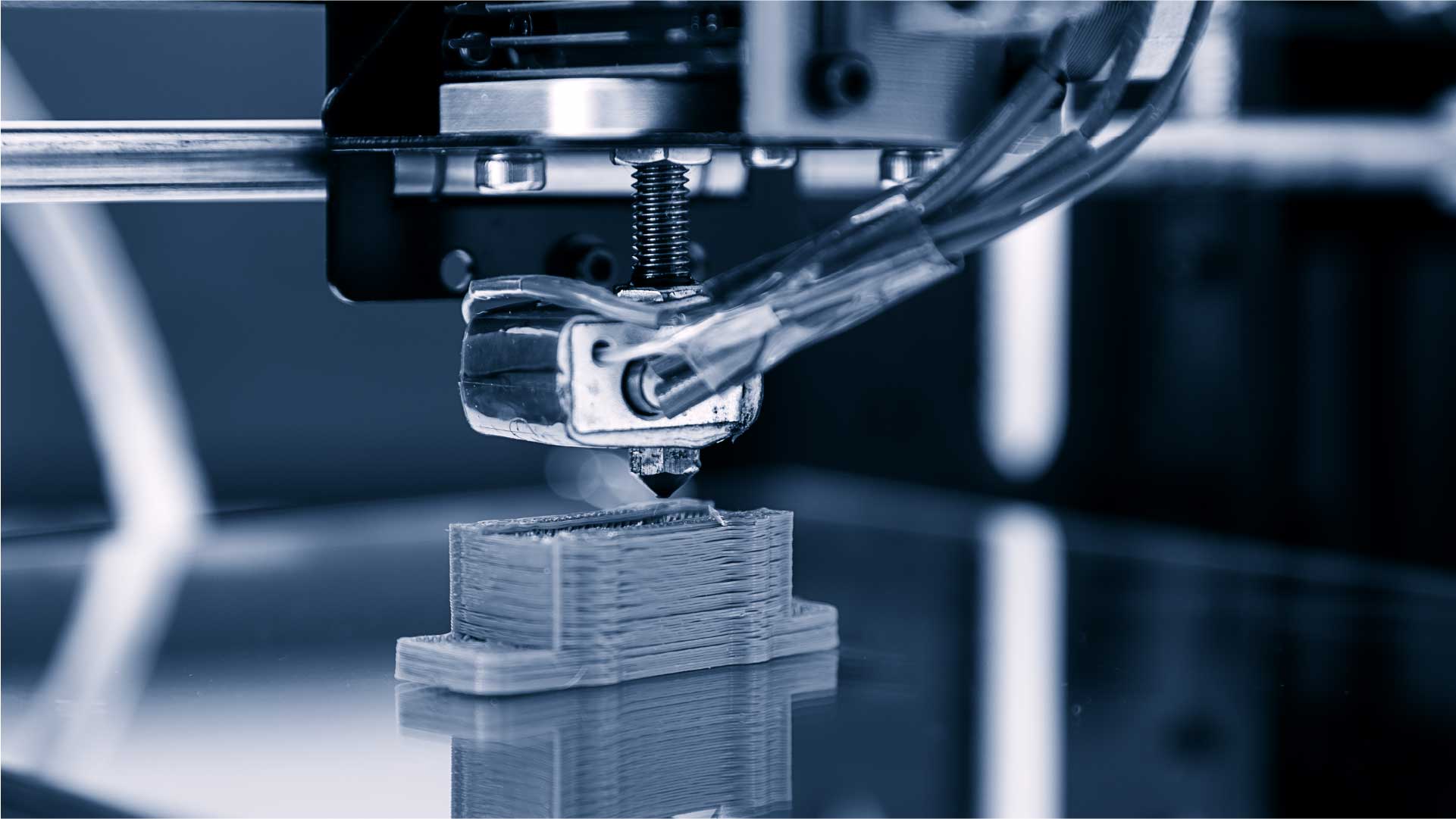

Additive manufacturing (AM) is an alternative approach to industrial manufacturing, which consists of adding layers of materials in precise shapes until the expected product is obtained. Additive manufacturing, often referred to as 3D printing, uses digital technologies to bring agility and efficiency to the manufacturing industry. It requires the combination of a Computer-Aided Design (CAD) software, printing hardware and materials (metals, thermoplastics, ceramics or biochemicals). Use cases today are mainly focused on small batch and high quality units (aerospace, military) and components with complex geometry (automotive, health). While additive manufacturing reached the top of its Hype Curve in 2013, it has seen renewed interest in the light of Covid-19: the general questioning of the supply chain’s dependence on Asian countries is giving new impetus to the idea of shortening supply chains and producing closer to the consumer market. The order established by Western companies — produce in the East, sell in the West — is being questioned.

Based on our current understanding of today’s challenges and opportunities, we wanted to share 3 main beliefs about AM:

- AM must be a lever for a more sustainable economy. AM has a direct impact on the raw materials manufacturing chain: extraction > manufacturing > distribution. By assessing the overall impact of AM on a product’s energy footprint, studies (US DoE, Digital Alloys) show that additive manufacturing greatly reduces the overall energy consumption required to produce a part, in addition to the savings made by reducing the international transportation of goods. It is interesting to note that the energy required to melt and bond materials — despite the wide disparity in energy required between metals such as titanium and polymers — is greater in additive manufacturing than in traditional manufacturing to process a unit. AM requires materials to be in powder or wire form to be processed (thus requiring more pre-treatment than billets used in conventional manufacturing) and processes such as Laser Powder Bed Fusion require nearly 4 times more energy than traditional Command & Control (CNC) machining to produce the same result. However, a 3D printed part represents only about 1/4 of the total energy required by conventional manufacturing. The overall difference comes from the fact that CNC machining traditionally begins with billets. The aerospace buy-to-fly ratio (the ratio of material purchased to material used in the part being manufactured) ranges from 6:1 to 33:1, which means that up to 97% of the raw material is wasted. By adding only the material needed for the part, AM allows massive cuts here. Moving now from this product-centric vision to an international vision implies a massive shift in energy demand from manufacturing countries to Western countries. With the traditional supply chain, the energy used for manufacturing is managed by the country of manufacture (in short: Southeast Asia). With AM, it is now up to Western countries to provide the energy needed for printing and processing. Therefore, if the total energy footprint of the product decreases, this leads to a substantial increase in energy demand from Western countries.

- Mass customisation using AM is difficult. Although there is a technical justification for allowing AM to mass produce unique parts, it raises a series of questions about unit quality assurance, standardization of lifetimes and warranties, and security. Currently, producing the same quantity of a given mass product in its equivalent of custom units raises uncertainties about production time. While printing itself is becoming increasingly efficient, it still requires post-processing, which can be time-consuming and may require a traditional production line — not really suited to a highly decentralized production organization as advocates of AM often fantasize.

- Finally, AM requires a dense community to achieve maximum efficiency. A network of 3D model suppliers, decentralized production units, material suppliers, distribution and logistics providers, and circular economy/recycling experts. Today, this network is not yet fully empowered because the infrastructure — both physical and digital — is in the middle of its development.

In conclusion, the additives industry can address issues of sustainability, society and geostrategy, but if change is made, countries need to prepare the underlying infrastructure necessary to enable optimal efficiency.

2 Key Figures

220 additive manufacturing startups

listed worldwide (created after 2005)

Market size expected to reach $22bn by 2022

According to Formlabs, the 3D printing market, with sales of $6bn in 2017, is projected to grow at a compound annual rate of 30.2% to reach a total market size of $22bn by 2022.

3 startups to draw inspiration from

This week, we identified three startups that we can draw inspiration from: Essentium, AMFG and Xometry.

Esentium

Essentium is a US-based startup providing printers and materials for Aerospace, Automotive, consumer goods and biomedical industries. The company works with the High Speed Extrusion process.

AMFG

AMFG is a UK company offering an end-to-end software that automates human tasks needed in the AM process, thus enabling faster and larger volume manufacturing, at a lesser cost..

Xometry

Xometry is a US company that has raised $118M to become the one-stop shop for all AM-related services. Among others, it provides a vast production-as-a-service platform connecting decentralized manufacturers with companies in need of production capacity.

123Fab #4

1 topic, 2 key figures, 3 startups to draw inspiration from

Earlier this week we mentioned the situation of warehouse workers. While we presented a few companies specialized in autonomous robots, the market for connected workers is also booming.

Connected workers are better connected to their work environments thanks to the digital technologies they benefit from, which enable better communication, quantification and remote support. These technologies are usually a combination of hardware, software and AI. The adoption of the latter is facilitated by the increasing demand for productivity and employee safety and well-being.

Smart wearables for Industry 4.0 are therefore spreading in factories and warehouses to support workers in all their tasks. Smart headsets (headgear and goggles), mobile devices (watches, tablets) or protective gear (textiles, hearing gear) are among the most common wearables.

2 Key Figures

600 work accidents per minute in the world

(International Labor Organization)

Market size expected to reach $9.9bn by 2026

According to Polaris, the connected worker market will be worth $9.9bn by 2026.

3 startups to draw inspiration from

This week, we identified three startups that we can draw inspiration from: Fieldbit, Parsable and Canaria.

Fieldbit

The Israeli company is specialized in connected headsets with Augmented Reality, providing employees with extensive field information.

Parsable

The US company has raised $73M to digitize industrial processes that were previously paper-based. It covers use cases such as inspection, issue management, precision work execution or training.

Canaria

The company originally won a NASA contest before applying its cognitive fatigue tracking device to industrial workers. It monitors workers’ fatigue and predicts medical events before they happen.