France’s Extended Producer Responsibility (EPR) framework, based on the “polluter-pays” principle, holds companies accountable for the entire life cycle of these products, from design to end-of-life.

While EPR has existed in France since 1975, it gained traction in 1992 with the household packaging decree and has since expanded to include sectors such as batteries, paper, and electrical and electronic equipment.

The major new development for 2025 is the expansion of this system to include industrial and commercial packaging (Emballages Industriels et Commerciaux – EIC). This marks a significant regulatory evolution, applying the “polluter-pays” principle to B2B packaging waste for the first time. The goal is to improve waste collection, sorting, and recycling while encouraging producers to reduce material use and invest in sustainable alternatives.

What types of packaging are affected?

The scoping study for the upcoming EPR scheme highlights that professional packaging is used across all business sectors:

- Chemical and pharmaceutical

- Cosmetics and personal care

- Manufacturing

- Textile

- Automotive

- Construction

- Transport and logistics

- E-commerce

Professional packaging includes all material used in a B2B context, including:

- Sales packaging: cans, sachets, big bags, metal drums, etc.

- Grouping packaging: cardboard boxes, plastic wrap, etc.

- Transport packaging: pallets, crates, etc.

This new regulatory framework goes beyond waste management. It is already influencing internal strategic decisions across affected industries. The obligation to manage and finance end-of-life packaging will necessarily drive companies to reconsider their materials usage, explore circular models, and implement innovative packaging solutions.

Before considering reuse, recycling or new materials, the top priority remains sobriety (i.e. reducing packaging at the source). Minimizing packaging volume and eliminating unnecessary materials is the most effective way to reduce environmental impact, and often the most cost-efficient.

Key solutions for a circular packaging system

- Reusable packaging

One of the most impactful solutions lies in reusable packaging systems. These systems drastically reduce demand for raw materials and eliminate single-use packaging by encouraging reuse cycles.

As an example: Loop partners with major brands like Nestlé to distribute products in durable, reusable containers. Once used, the packaging is collected, cleaned, and refilled—minimizing waste and optimizing material use.

- Recycled materials and bioplastics

Switching to recycled or bio-based materials can significantly reduce the environmental burden of packaging. These alternatives, often recyclable themselves, support circularity and reduce reliance on fossil-based plastics.

French startup Carbios is pioneering enzymatic recycling, a breakthrough technology that breaks down PET plastics into their base components for infinite reuse. This innovation could redefine how industries handle plastic waste.

- Packaging management tools

Smart tools can help companies monitor, reduce, and optimize their packaging usage. Digital platforms and traceability systems ensure compliance with evolving EPR regulations while making sustainability efforts more transparent.

Blockchain, for instance, can facilitate the tracking of reusable packaging throughout its life cycle, allowing companies to verify returns and reward responsible practices.

- Modular packaging

Modular packaging systems enable businesses to create packaging that fits products precisely—reducing excess material, cutting storage costs, and streamlining transport.

Packsize offers on-demand packaging solutions, allowing companies to custom-size boxes for each shipment. E-commerce players like Amazon already use this approach to reduce void fill and improve shipping efficiency.

- Natural materials

Packaging made from natural plant-based fibers—such as straw or hemp—offers a renewable, biodegradable alternative to conventional materials.

Startups like Xampla, develop plant-based materials that can replace single-use plastics. Their products, derived from pea protein, are biodegradable and suitable for various industries.

Looking ahead

As the new EPR law reshapes the industrial packaging landscape, companies are being called to adapt—not only to comply, but to lead. Circular packaging solutions like reusable systems, bio-based materials, smart management tools, and precision-fit packaging are already demonstrating how innovation and regulation can go hand in hand.

By embracing these sustainable alternatives, businesses can reduce their environmental footprint while building more resilient, future-ready supply chains.

2 Key Figures

7.5 million

tons of professional packaging were placed on the French market in 2024

7%

the rate of re-use of professional packaging in France

3 startups to draw inspiration from

Pandobac

This French startup offers a turnkey service for the rental, tracking, and washing of reusable transport crates. The solution is tailored for B2B flows between food industry players—whether between manufacturers, retailers, or out-of-home catering providers. It enables companies to reduce single-use packaging while simplifying reverse logistics.

Xampla

A british startup that, manufactures plant-based, biodegradable packaging materials. Its product range includes stretch films, wrapping papers, and microcapsules—suitable for applications from homecare and cosmetics to packaging.

Lactips

Lactips produces water-soluble and biodegradable thermoplastic pellets using casein, a milk protein. The pellets can be used to make all sorts of packaging material.

Interested in a startup landscape or in an insights report?

Please fill out our contact form so that we can get back to you very quickly with our product offer.

Want to subscribe to our 123Fab?

Fill out our form to receive the latest insights into your inbox.

123Fab

1 topic, 2 key figures, 3 startups to draw inspiration from

Hydropower is a form of renewable energy that draws its power from the movement of water. Today, it accounts for over 20% of global electricity production.

Hydropower plants: towards small-scale and modular solutions

Hydropower, one of the oldest electricity production methods, generates up to 90% of electricity in countries like Norway, Brazil, and Canada. However, large-scale projects like China’s Three Gorges Dam have raised concerns due to their environmental and social impacts, including biodiversity loss and population displacement.

To address the drawbacks of traditional hydropower, innovators are developing solutions:

- Smaller-Scale Designs: Startups like Turbulent create modular vortex turbines that minimize environmental impact by operating without large dams.

- Fish-Friendly Turbines: Companies like Natel Energy are pioneering turbine designs that greatly improve fish survival rates.

- Standardized Containers: NuSTREEM’s NuCONTAINER system uses prefabricated standard shipping containers as powerhouses, reducing foundational requirements and on-site construction.

Tidal energy: taping the ocean’s energy

Tidal energy is generated from the natural rise and fall of the tides, caused by the moon’s gravitational pull. In France, the Rance tidal power plant—opened in 1966—was the first in the world and remains the only one in the country still operating today.

While traditional plants like Rance use the tidal range to produce electricity, newer technologies focus on tidal stream generators, which look like underwater wind turbines. Off the coast of Brittany, for example, these turbines help power the island of Ouessant by capturing the energy of moving water.

To further reduce environmental impact and expand deployment, other innovative solutions are being developed:

- Underwater Kites: Swedish startup Minesto is pioneering “underwater kite” systems that can generate electricity in slower currents, vastly expanding potential deployment areas.

- Floating Platforms: Companies like Orbital Marine Power are developing floating tidal turbines, making installation and maintenance easier while reducing environmental impact.

- AI-Optimized Arrays: Machine learning algorithms are being developed to optimize the placement and operation of tidal turbine arrays, maximizing energy capture.

Wave energy: unlocking the motion of the sea

Oceans, considering that about 70% of the Earth’s surface is taken by water, have not been well tapped for energy. There are various systems in place, namely floating and submerged devices, but most are at the development stages. The International Energy Agency estimates wave energy can provide as much power as 60 nuclear plants combined.

To tap into this vast resource, several companies are developing innovative solutions:

- Grid Connected Wave Energy Array: Eco Wave Power develops patented technology that captures wave energy from coastal structures and converts it into electricity.

- Offshore Buoys: Sweden’s CorPower Ocean has designed a compact wave energy converter in the form of a buoy, inspired by the pumping motion of the human heart, increasing efficiency in capturing wave energy.

Seawater thermal energy: heat from the sea

Seawater thermal energy utilizes the temperature differential between warm surface seawater and cooler deeper water to provide heating and cooling solutions. Through heat exchangers and pumps, this process transfers thermal energy from the sea into climate control systems for buildings located near the coast. Monaco for instance, produces nearly 20% of its energy from seawater heat pumping.

Rain-powered solar panels: a future innovation

Researchers from Tsinghua University in China are currently working on a new type of solar panel that can generate electricity even in the rain.

2 Key Figures

20%

Hydropower accounts for 20% of the world’s total electricity and 90% of global renewable energy

X2

To meet net zero goals hydropower needs to double by 2050

3 startups to draw inspiration from

Minesto

Founded in 2007 as a spin-off from Swedish aerospace manufacturer Saab, Minesto is a developer of marine energy technology. The company offers an innovative underwater kite-like structure equipped with a horizontal-axis turbine, designed to efficiently extract energy from the ocean and tidal currents, even at low velocities.

Turbulent

This Belgian startup aims to provide reliable and affordable energy to even the most remote communities. Turbulent Hydro has developed an innovative vortex turbine that generates low-cost electricity without requiring large-scale infrastructure projects or causing significant environmental impact.

CorPower Ocean

A Swedish company developing wave energy converters to generate clean electricity from ocean waves. Their technology uses a unique system inspired by the pumping principle of the human heart, with a heaving buoy on the surface that absorbs energy from waves.

Interested in a startup landscape or in an insights report?

Please fill out our contact form so that we can get back to you very quickly with our product offer.

Want to subscribe to our 123Fab?

Fill out our form to receive the latest insights into your inbox.

Before diving into treatment technologies, we recommend reading the first article in this series, where we explore what PFAS are and their devastating environmental and health impacts.

PFAS (per- and polyfluoroalkyl substances) are a group of synthetic chemicals widely used in industrial and consumers products. Due do their persistence and resistance to degradation, they accumulate in the environment and pose significant health risks. Addressing PFAS contamination requires a combination of well-established and emerging treatment technologies that focus on treatment, and increasingly, destruction.

Mature PFAS treatment technologies

Several well-established technologies are currently used for PFAS removal, including:

- Granular Activated Carbon (GAC): One of the most studied methods for removing PFAS, commonly used in drinking water treatment. It helps absorb organic compounds, as well as taste, odor, and synthetic chemicals. GAC works well for longer-chain PFAS like PFOA and PFOS but is less effective for shorter-chain ones like PFBS and PFBA, which don’t adsorb as easily.

- Anion Exchange Resins (AER): They are like tiny magnets that attract and hold onto impurities, preventing them from passing through the water system. Negatively charged PFAS are attracted to the positively charged anion resins. This method can treat almost all PFAS chain lengths but is more expensive than GAC.

- Nanofiltration or Reverse Osmosis Membranes: High-pressure membrane filtration systems, i.e. nanofiltration and reverse osmosis, have been highly effective in eliminating over 90% of PFAS, including short-chain compounds.

Emerging PFAS treatment technologies

A few new innovative technologies are being developed to enhance PFAS removal efficiency:

- Selective Absorbents: Companies like Puraffinity are pioneering precision technologies to target PFAS removal. Their Puratech absorbent solution is designed to integrate seamlessly into existing treatment systems and can be tailored to capture specific PFAS compounds.

- Foam Fractionation: Oxyle has developed a multi-stage foam fractionation, catalytic destruction, and machine learning monitoring process. This method has shown to eliminate over 99% of PFAS.

While these technologies improve PFAS capture, they do not destroy the compound. This limitation has driven interest in developing destruction technologies.

Emerging PFAS destruction technologies

Unlike traditional removal methods, destruction technologies aim to completely break down PFAS compounds rather than simply capture them. While holding promise, these technologies are still energy-intensive and costly.

- Supercritical Water Oxidation (SCWO): This oxidation process converts organic contaminants into water, carbon dioxide, and inert mineral residue. 347Water has developed AirSCWO systems, which have been proven effective in destroying PFAS-laden ion exchange resins.

- Electrochemical Oxidation: This technique is an electrochemical reaction that degrades PFAS compounds on a large scale while producing little to no waste, making it a potential solution for large-scale PFAS degradation.

Additionnally, researchers are working on next-generation PFAS destruction technologies such as low-temperature mineralization, plasma technology, and sonolysis.

Destruction technologies require high PFAS concentrations to be effective and tend to be energy-intensive, making them less suitable for diluted waste streams. Furthermore, these technologies are quite immature, requiring validation before large-scale deployment. To address these challenges, technology providers have been exploring hybrid solutions that combine both removal and destruction methods to provide a holistic solution. For instance, Gradiant has developed a technology that enables on-site PFAS removal and destruction, eliminating the need for waste handling, landfilling, or incineration.

3 startups to draw inspiration from

Oxyle

A Swiss start-up that developed a technology which is claimed to have over 99% removal of PFAS with lower energy use compared to traditional methods. The three-stage process involves foam fractionation, catalytic destruction, and machine learning monitoring.

Gradiant

A U.S.-based water and wastewater treatment solutions provider, Gradiant has developed ForeverGone, a technology that is capable of removing and destroying PFAS on site, without the need for waste handling, landfilling, or incineration. It is different from conventional solutions such as granular activated carbon (GAC) and ion exchange

Puraffinity

A UK-based start-up which focused on developing precision technologies for the removal of PFAS from water. Puraffinity has developed an absorbent solution called Puratech, which integrates perfectly into existing water treatment systems and can be adapted to target specific PFAS compounds.

Interested in a startup landscape or in an insights report?

Please fill out our contact form so that we can get back to you very quickly with our product offer.

Want to subscribe to our 123Fab?

Fill out our form to receive the latest insights into your inbox.

Once unknown, perfluoroalkyl and polyfluoroalkyl substances (PFAS) are now among the most pressing environmental crises. These “forever chemicals” are ubiquitous—from remote ecosystems to human tissues.

France has taken a major step in regulating PFAS, joining a growing list of countries pushing for stricter controls. A new law adopted on the 20th February 2025 aims to curb the use of these persistent pollutants, addressing contamination risks and protecting public health. But what exactly are PFAS, and why are they so concerning?

The Science Behind PFAS

PFAS are a large group of more than 10,000 man-made chemicals that have been used in industries and consumer products since the 1940s. Their most notable feature is that they are extremely persistent, due to their carbon-fluorine bounds, which are the strongest bonds in organic chemistry. This persistence, which maklqe them useful for manufacturing, also causes them to resist natural breakdown, remaining in the environment for hundreds of years.

Adding to the problem, PFAS are highly mobile, detected in rainwater from Tibet to groundwater in industrialized nations. Short-chain and ultrashort-chain PFAS, such as TFA, are particularly troubling due to their ability to infiltrate living cells and bypass most filtration systems.

An investigation by Le Monde and 17 other media identified more than 17,000 contaminated sites across Europe. More than 2,100 of these sites were classified as “hot spots” with pollution levels considered hazardous to human health.

The Devasting Impact of PFAS

Studies have linked exposure to PFAS to severe health conditions, including:

- 57% increased risk of kidney cancer

- 25% reduction in immune function in children

- Elevated cholesterol levels

- Various cancer

Industries Driving PFAS Contamination

The biggest contributors to PFAS pollution are the manufacturers of these chemicals, including large companies such as AGC, Arkema, Daikin, Gore and Syensqo (formerly Solvay). Chermours (formerly DuPont) and 3M are the companies that created these products and contributed to their widespread use. Today, various industries contribute to their further spread:

- Textiles: PFAS are commonly used in raincoats and sportswear to make them waterproof and stain resistant. In 2024, the market for perfluoroalkyl and polyfluoroalkyl substances in this segment is worth $4.4 billion.

- Food packaging & cookware. Some PFAS are used in cookware (i.e. in Teflon pans), food packaging, and in food processing for their non-stick and grease, oil, and water-resistant properties

- Electronics: PFAS play a crucial role in semiconductor manufacturing, particularly in photolithography and equipment components. Their resistance to heat and low surface tension minimize defects, improve chemical compatibility, and increase equipment lifespan. The size of the market for PFAS in electronics stands at $9.1 billion in 2024.

- Cosmetics: PFAS contributes to the performance of waterproof makeup, long-lasting foundations, and anti-aging skincare products.

- Automotive & aerospace: Known for their heat resistance and non-corrosive properties, PFAS are essential in various automotive and aerospace applications.

Perspectives On Regulation

The European Union has implemented stringent regulations to restrict the use of. Key regulations include:

- Persistent organic pollutants (POP) regulation: In line with the Stockholm Convention, this regulation has banned several PFAS substances, including PFOS (perfluorooctane sulfonic acid) since 2009, PFOA (perfluorooctanoic acid) since July 2020, and PFHxS (perfluorohexane sulfonic acid) since June 2022.

- Registration, evaluation, authorization & restriction of chemicals (REACH): A REACH proposal aims to ban the manufacture, use, and placing on the market (including imports) of at least 10,000 PFAS substances.

- Drinking water directive: This directive sets a maximum PFAS concentration of less than 0.5 ppt in drinking water effluent to ensure water quality and public safety.

2 Key Figures

Over 10,000

PFAS include more than 10,000 synthetic chemical compounds used in industrial and consumer products.

€100 Billion

The estimated annual cost of removing even a fraction of short-chain and ultrashort-chain PFAS from the environment and destroying them, surpassing two trillion euros over 20 years.

123Fab #103

1 topic, 2 key figures, 3 startups to draw inspiration from

Microplastics—plastic fragments smaller than 5 millimeters—originate from two main pathways:

- Primary microplastics are intentionally manufactured at microscopic scales, such as microbeads in cosmetics or fibers from synthetic textiles.

- Secondary microplastics are created when larger plastics break down over time due to environmental factors like sunlight, wind, and water.

Over time, these tiny particles infiltrate ecosystems, contaminating soil, waterways, and even human blood. Recent studies reveal that microplastics have been detected in the bloodstreams of up to 80% of the people tested, raising serious concerns about their long-term health impacts.

Faced with this crisis, companies are taking steps to tackle microplastic pollution. For instance, Nestlé Waters is participating in the Plastic Trace Project (2022–2025), which aims to standardize the tracking of microplastics in water, food, and the environment.

Key industries responsible for microplastics

The variety of consumer and commercial products that are intentionally loaded with microplastics is vast: cosmetics, detergents, paints, medicines, diapers, pesticides, and more. The International Union for Conservation of Nature (IUCN), identifies seven sources of microplastics in marine environments:

- Synthetic textiles (>50%): Washing synthetic clothes discharges millions of microfibers into wastewater.

- Vehicle tires (10-20%): The EU alone generates around 0.5 million metric tons of microplastics annually from tire wear, and this is expected to increase with the rise of electric vehicles that are typically heavier.

- Urban dust (10-20%): These come out of the sum of several sources that involve artificial turf, building paints, and industrial abrasives.

- Road marking (3-5%): Everything, including the roads’ infrastructure deteriorates. Hot-melt paints used for road markings contain polymer binders that contribute to microplastic pollution.

- Marine coating (4%): The coatings applied to ships’ hulls break down over time, contributing to the load of microplastics in the oceans.

- Personal care products and cosmetics (1-2%): Most skincare and cosmetics products contain microbeads, a well-known source of microplastic pollution. Since 2023, the EU called for a ban for microplastics in consumer products, including cosmetics.

- Plastic pellets (0.3%): Resin pellets, which are used as raw material in producing plastic items, often spill into the environment.

These categories only scratch the surface. Microplastics have countless other sources, many of which remain poorly quantified. Our understanding of the problem is still evolving, but the urgency to act is clear.

Solutions

Efforts to address microplastic pollution focus on two main strategies: reducing pollution at its source and improving filtration systems to capture particles before they reach the environment. Here’s how different industries can contribute:

- Textile industry:

- Developing alternative fibers: Dutch startup Boldwill produces microplastic-free sports apparel. The company uses hemp, cotton, and fabrics made from eucalyptus and beech trees in its sportswear.

- Installing filters in washing machines: A variety of filters are being developed capable of catching fibers before they go into the wastewater system. One example is the innovative filtration technology of Matter, originally developed for washing machines. Today, its solutions extend to industrial applications, stopping microplastic entry into sewage sludge.

- Automobile industry:

- Durable tire materials: Projects like LEON-T are developing and testing airless tires for heavy vehicles. This would reduce friction of rubber material and minimize particulate emissions.

- Tyre dust catchers: The Tyre Collective has designed a device to capture tire dust directly at the source. This device is placed behind the wheel and uses both a suction system and an electrostatic capture system to capture the plastic microparticles.

- Manufacturing:

- Industrial filtration solution: Companies like IADYS or ECOFARIO are developing technologies to capture microplastics during industrial processes

- Alternative materials: For instance, Naturbeads offers cellulose-based microspheres as a viable substitute for microplastics in everyday products.

- Packaging:

- Plastic-free alternatives: Companies are manufacturing new materials that will replace traditional plastics. For example, Lactips produces water-soluble and biodegradable thermoplastic pellets using casein, a milk protein. The pellets can be used to make all sorts of packaging material.

- Cosmetics:

- Biodegradable alternatives: Cosmetic products can be reformulated to be microplastic-free. A French company, Dionymer, has developed a 100% biosourced and biodegradable polyester obtained by fermentation for use in make-up and skincare formulas.

- Agriculture:

- Bio-based fertilizers: BioWeg has developped AgriWeg a biodegradable emulsion for the substitution of coatings from petroleum and acrylic based materials on fertilizers and seeds.

2 Key Figures

51 trillion

According to the UN, there are as many as 51 trillion microplastic particles in the seas, 500 times more than stars in our galaxy.

Between 78,000 and 211,000

The average person eats, drinks, and breathes between 78,000 and 211,000 microplastic particles annually.

3 startups to draw inspiration from

Naturbeads

A UK based-startup commercializing biodegradable, cellulose-based ingredients, offers a sustainable alternative to plastic microbeads used in personal care products, paints and coatings, packaging, adhesive and many other industrial products.

ECOFARIO

The German startup ECOFARIO develops microplastics removal systems for wastewater treatment plants. Its High-G-Separator uses hydrocyclone-based separation technology, eliminating the need for filter media to separate microplastics.

PlanetCare

A Slovenian startup that has developed innovative filters capturing 90% of synthetic fibers that are being released from textile products during each wash.

Interested in a startup landscape or in an insights report?

Please fill out our contact form so that we can get back to you very quickly with our product offer.

Want to subscribe to our 123Fab?

Fill out our form to receive the latest insights into your inbox.

123Fab #102

1 topic, 2 key figures, 3 startups to draw inspiration from

The circular economy redefines traditional economic models and contrasts with the “take-make-waste” linear approach. In the latter, resources are extracted to create products that later become waste, with very limited uses or value recovery. Circular economy, on the other hand, emphasizes sustainability, keeping materials in use for as long as possible while minimizing waste and resource consumption.

Key frameworks such as the Value Hill and the Butterfly Diagram shed light on how this system works: the Value Hill describes how to maintain and regain value at every stage in a product’s life, while the Butterfly Diagram helps to visualize infinite cycles of reuse and regeneration within an economy. (For more information, read those articles on the Value Hill and Butterfly Diagram.)

At its core, the circular economy is guided by seven pillars, each offering actionable strategies to reduce waste, optimize resource use, and foster innovation. Let’s delve into these principles and their potential for transformative change in driving sustainability.

The 7 Pillars of the Circular Economy (as defined by l’ADEME)

- Sustainable procurement: This involves considering the environmental and social impacts of resource extraction and usage, with the aim of minimizing waste and greenhouse gas emissions. The goal is to prioritize sustainable resources by choosing suppliers based on ethical and environmental standards, aligning with the overall circular model.

- Eco-design: This involves considering the entire life cycle of a product or service, from the design stage onwards, to limit its impact on the environment. A very good example is the Renault Scenic E-Tech Electric, with its high rate of recycled materials in the manufacture of the car. Many parts are designed to be recyclable at the end of their life to reduce its ecological impact as much as possible.

- Industrial and territorial ecology (or industrial symbiosis): This pillar connects various economic actors to optimize the use of local resources such as water, energy, materials, waste, equipment, and expertise. By sharing resources, one company’s waste becomes another’s resource. The most representative example of industrial symbiosis is the one in Kalundborg, Denmark, where companies like Novo Nordisk (pharmaceuticals), Ørsted (energy), and Kalundborg Municipality collaborate to share resources such as steam, water, and industrial by-products. This innovative collaboration not only optimizes resource use but also drives significant cost savings and reduces the overall carbon footprint.

- Service economy: In this model, usage is prioritized over ownership. It emphasizes offering services connected to products rather than selling the products themselves, which extends their lifespan without consuming more material resources or energy, creating jobs, and encouraging sharing. A notable example is Michelin‘s “Tyre as a Service” model, where the company retains ownership of the tires and manages their entire lifecycle—maintenance, retreading, and recycling. Thus, customers are charged based on usage: per kilometer for trucks and per landing for airplanes.

- Responsible consumption: Consumers, whether individuals or organizations, must consider the environmental and social impacts of products at every stage of their life cycle. This means choosing sustainable products and adopting eco-conscious consumption habits. Key questions include: Do I really need this? Is the product recyclable? What materials were used? How was it made?

- Extending product lifespan: Consumers should opt for repairing, reusing, or donating unused or broken items to give them a second life. This not only benefits the environment but also supports circular business models and offers financial savings. For example, Back Market, a French platform specializing in refurbishing electronic products, collects smartphones, computers, and other devices nearing the end of their life, repairs them, and resells them, reducing e-waste and offering affordable products.

- Recycling: This is the final phase of the circular economy whereby existing materials are converted to other new forms. The process is to recover and reduce the amount of waste by recycling into raw materials. This closes the cycle as recycled materials start being used for procurement. For instance, ROSI provides an innovative solution for recycling and valorization of raw material in the photovoltaic industry. Their technology can recycle all valuable raw materials in waste solar panels, including silicon.

How can companies benefit from the circular economy?

Businesses can significantly benefit from the adoption of circular economy principles through new profit opportunities, cost reductions from lower reliance on volatile raw materials and increased use of recycled inputs. New business models, such as rentals or leasing, also create stronger, long-term customer relationships by increasing touchpoints throughout a product’s lifecycle.

2 Key Figures

70%

Material extraction and use amount to 70 percent of global greenhouse gas (GHG) emissions.

7.2%

Only 7.2 percent of used materials are cycled back into our economies after use.

3 startups to draw inspiration from

Hubcycle

A French startup that specializes in upcycling food industry by-products into valuable ingredients. By sourcing vegetal by-products from industrial food processes before they are discarded, Hubcycle transforms them into ingredients for the food, pet food, cosmetics, and homecare sectors. This approach eliminates the need for new raw materials, reducing environmental impact and significantly lowering the carbon footprint for both suppliers and customers.

GreyParrot

A UK startup, leading the way in AI-driven waste analytics for the circular economy. GreyParrot aims to increase transparency and automation in waste management, unlocking the hidden financial value of waste. With its advanced AI-powered computer vision systems deployed globally in sorting facilities, the platform can monitor, analyze, and sort waste at scale. GreyParrot’s insights will help waste managers, producers, and regulators increase recycling rates.

Faircado

Berlin-based, Faircado has created a browser extension designed to promote the circular economy. The idea is simple: thanks to artificial intelligence, the extension uses a combination of image and text matching to suggest second-hand alternatives when you search for a product on the Internet. Faircado supports 1,600 sites, including Amazon, Zalando, Patagonia and Apple. These recommendations come from over 50 partners, including eBay, Back Market, Grailed, Rebuy, Vestiaire Collective…

Interested in a startup landscape or in an insights report?

Please fill out our contact form so that we can get back to you very quickly with our product offer.

Want to subscribe to our 123Fab?

Fill out our form to receive the latest insights into your inbox.

Context

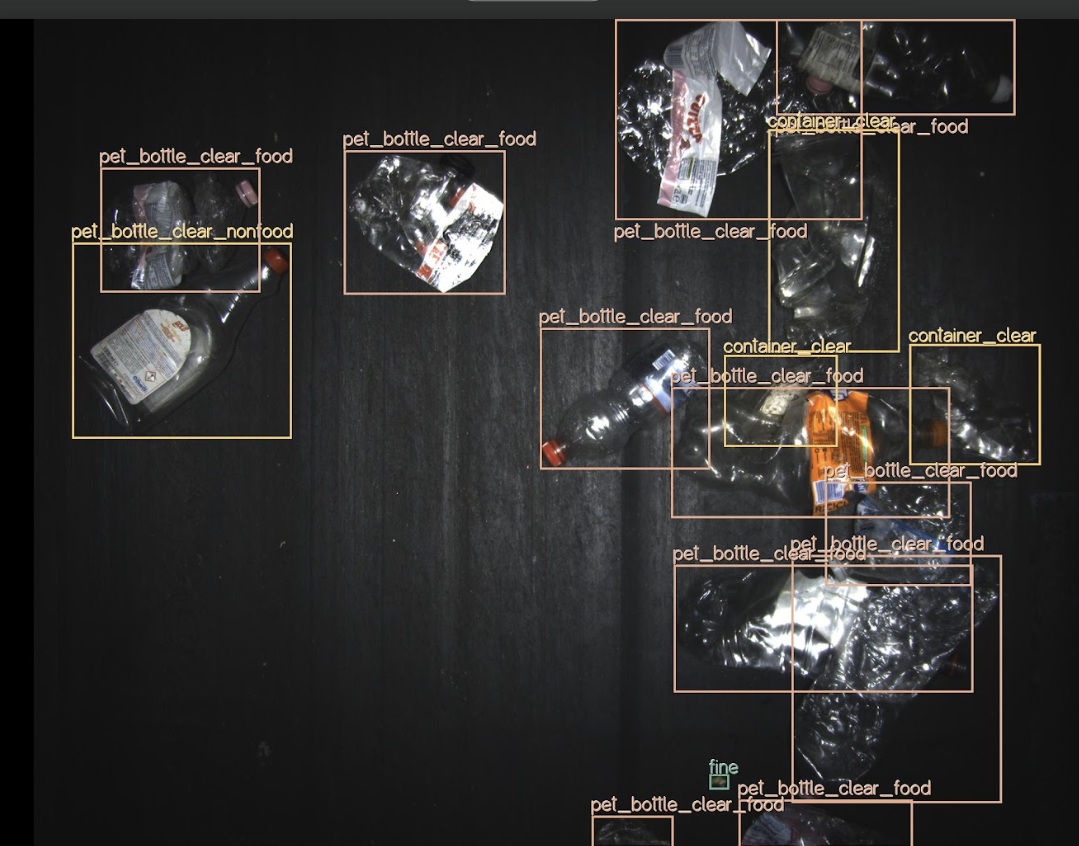

Our client has developed a strong innovation activity in order to fuel its transformation. In this context, our client asked us to conduct a deep dive study on waste characterization.

Mission

We carried out a study to define the go-to-market strategy:

- Market study on megatrends and key forces shaping the industry

- Competitor benchmark and illustration of corporate-startup partnerships

- Funding analysis and illustrations of the latest investments

- Patent volume and key patent filer analysis

- Technology mapping introducing 5 segmenting criteria for the scope

- Sourcing of all startups in the field, and scoring them to narrow the list down to highly qualified stones

- Creating collaboration scenarios with each qualified startup and drafting of fact sheet one-pagers for top-rated partners

Key figures

2

Visits to sorting facilities

11

Explorations of specific use cases

56

Startups sourced and assessed

1

Year of quarterly updates on weak signals

123Fab #86

1 topic, 2 key figures, 3 startups to draw inspiration from

This 9 May, the COP15 against desertification opened in Abidjan, Côte d’Ivoire. The challenge is to take concrete action against land degradation and its harmful consequences for biodiversity and populations. Today, according to the UNCCD, more than 40% of the planet’s land is degraded, affecting half of humanity and threatening half of the world’s GDP, i.e. $44,000 billion. This is particularly due to the impacts of climate change and the increase in the number of disasters such as droughts causing aridity of the land and water scarcity. Ethiopia is currently experiencing the worst drought “ever”: in 18 months, no drop of rain has fallen. The African continent is not the only one affected: while North America is experiencing an unprecedented drought, the worst episode recorded in 1,200 years, in the south of the continent, Chile is preparing for water rationing. The worst is also to be feared in France as several regions are also experiencing historic droughts.

These droughts are a big problem for communities, especially in terms of access to water for the population, agriculture, the surrounding fauna and flora, and the damage that can be caused. To mitigate the risks of water scarcity, various levers have been tested around the world. Beyond a better distribution of water sources, with the creation of aqueducts, wells, aqueducts, or dams, some communities try to avoid evaporation of stored water. In 2015, in California, the water company Las Virgenes Water District poured as many as 96 million shade balls filled with water and air to reduce water evaporation by 85-90%. Following this initiative, start-ups have taken up this technology, such as Neotop Water Systems, which has developed “TopUp Ball”, a modular cover for water reservoirs that allows for significant reduction of evaporation while cooling the water, maintaining high quality and reducing the growth of algae. In addition, another lever mobilized is that of education, particularly for water-intensive activities, in more rational and sustainable use of water. In agriculture, which uses more than 70% of the available freshwater in most parts of the world, precise irrigation consists of having water brought right to the roots of the plants, exactly when the plants need it, and in just the right quantity they need. Smart irrigation, which uses weather data or soil moisture data to determine the irrigation need is also in vogue and has raised over $155 million in investment according to Tracxn.

Other initiatives focus on increasing existing freshwater resources:

- Desalination: It has been widely developed since the 1960s. More than 15,000 plants are producing desalinated water today, most in the Middle East and North Africa—the largest is in Saudi Arabia. But desalination is still very energy-intensive, although it is increasingly powered by renewable or recovered energy, and it represents a real danger for marine life and oceans, in particular, because of the very large discharges of brine.

- Wastewater filtration: Since the 1990s, some start-ups have been trying to address this market by offering filtered water quickly, cheaply, and without harming the environment. This is the case of Desolenator, which has developed a technology that uses the sun and seawater to produce high-quality drinking water from any source at a cost of less than $1 per cubic metre.

- Water from air: More than 50 companies are providing solutions to extract water from the air according to Tracxn. India-based startup Uravu Labs has developed the Aquapanel solution, based on solar thermal. It produces drinking water by absorbing water vapour at night when humidity levels are generally higher. Then, during the day, the solar collector heats the unit to 176-212 degrees Fahrenheit, which then releases the water vapour, which passes through an air-cooled condenser, eventually turning into liquid. A similar system, WEDEW, from the Skysource/Skywater Alliance partnership, won the XPRIZE Water Abundance award. The solution cools hot air through a biomass gasifier and stores the resulting condensation in a tank, which can then be accessed via a tap. It can harvest enough water from the air for 100 people per day.

- Fog water harvesting: It provides an alternative source of freshwater through a technique used to capture water from wind-driven fog. This strategy has been developed by the Canadian-Mexican start-up Permalution, which has created a solution based on biomimicry that makes it possible to harvest between 150 and 400 litres of water per day, i.e. 3 bathtubs, thanks to fog and while respecting the environment. In particular, it has helped save orchids from the brink of extinction as part of a forest fire mitigation strategy.

- Other sources of water such as clouds and icebergs are used on a small scale to alleviate the risks and problems associated with water shortages in the world.

Global warming is acting as a catalyst for droughts and water scarcity, which are becoming more severe and more frequent in all parts of the world. The consequences are noticeable, and many initiatives are being developed under the impulse of private companies, governments but also startups. Although they propose solutions to prevent or alleviate droughts in part, it seems that only a reduction in global emissions as well as a more reasoned consumption of water, particularly within industries, would make it possible to limit their future consequences.

2 Key Figures

The smart water management market size is expected to reach $23.46 billion, rising at a market growth of 10.4% CAGR between 2021-2027.

Business Wire

+$210M of funding in water management

Traxcn

3 startups to draw inspiration from

Desolenator

The UK startup has developed a water purifying device intended to purify water from any source. The company’s purifying device utilizes solar radiation to turn salt and contaminated water into pure drinking water, enabling people in coastal and water-stressed areas to become water independent.

Uravu Labs

The Indian startup has developed a technology to convert atmospheric moisture into usable water. The system is built with only a few components: the proprietary hygroscopic material that absorbs and stores water vapour from the air and a solar collector – similar to solar water heaters – that rapidly heats the vapour, which then turns into water when cooled.

Permalution

Created in 2020, the Canadian-Mexican start-up has developed a fog water harvesting technology that can capture from 150-400 liters of water per day, which can support a family of 4-6. It has also developed a water radar, which goes hand in hand with the technology. It is a passive solution and it does not alter ecosystems.

Interested in a startup landscape or in an insights report?

Please fill out our contact form so that we can get back to you very quickly with our product offer.

Want to subscribe to our 123Fab?

Fill out our form to receive the latest insights into your inbox.