123Fab #7

1 topic, 2 key figures, 3 startups to draw inspiration from

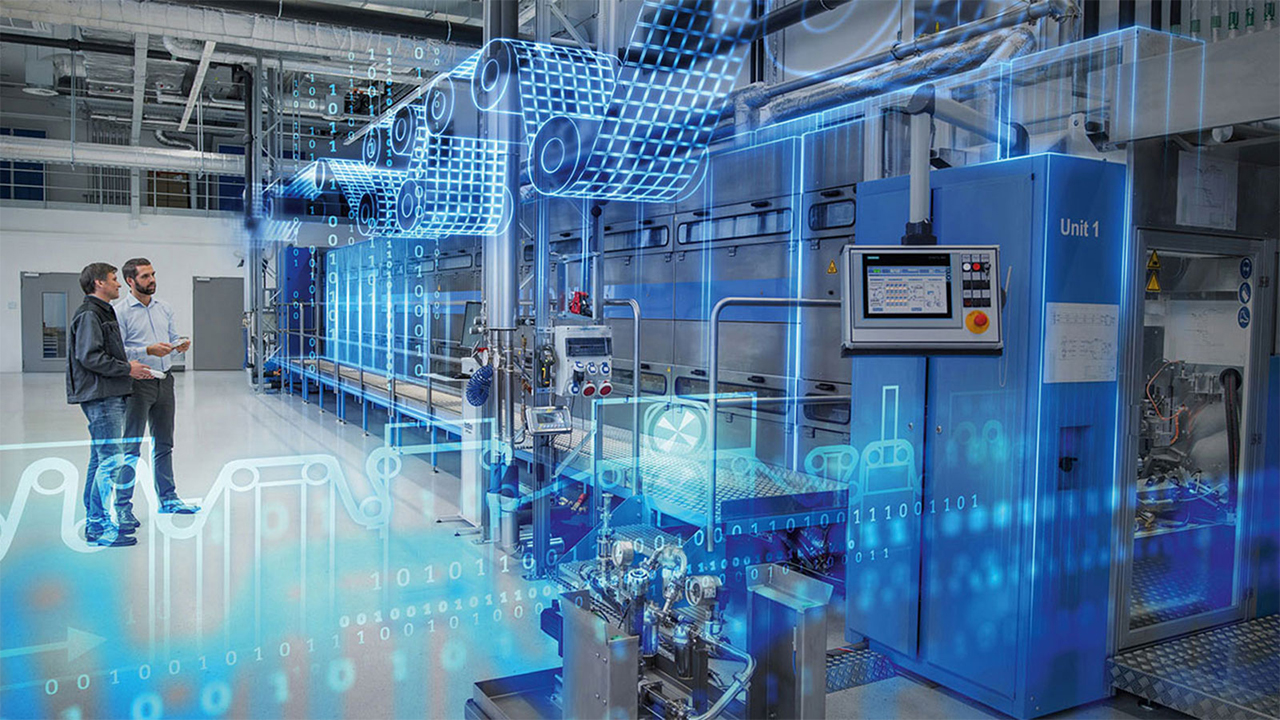

While a large portion of the working population is being asked to work from home when they can, the need for remote simulation and monitoring has increased dramatically. This has led us to address the increasingly relevant topic of ‘Digital Twins’, or how the combination of connected sensors, digital modeling and artificial intelligence work together to serve Industry 4.0. It is especially useful for remote operations: NASA was the first to really leverage twin technology to ensure the maintenance of its assets, thousands of kilometers away.

Digital Twins (DT) are a virtual representation of physical assets or networks. It is composed of three main elements:

- A physical part: the product, component, process or network to be twinned

- Its virtual replica: including the physical and chemical specificities of each material or component

- Data flow: coming from the connected physical product and enriching the virtual replica in real time, providing risk and performance information.

Digital Twins are therefore very different from a digital model since you start from the physical product to build its twin, and not the other way around. The idea of dynamics, of movement, is also crucial to understand the depth of DT and the variety of use cases.

In its most static form, DT transcribes real-time data from a physical asset, which facilitates testing and maintenance. Continuous data collection provides a thorough history of the physical asset’s performance and problems, and this data can feed machine learning algorithms to draw the line further into the future and improve their predictive capability. The so-called Predictive Twin is an extension of the original DT as it allows the execution of what-if scenarios. This allows you to save money by investing better (you can test a new product or a new part of your asset and see if it performs according to plan) and to support your operating decisions (for example, when operating a power grid, you can run a scenario on how the grid will behave if you shut down a generator, increase your renewable energy consumption, or experience a large increase in demand).

The main sectors interested in Digital Twins are Manufacturing, complex Engineering (aerospace, automotive, railway…), Health, Energy, but also network operations (grid operators, logistics and supply chain). Chevron, for example, expressed the ambition to save millions a year thanks to digital twins.

However, the deployment of Digital Twins is slowed down by a series of technical and organisational complexities:

- From a technical point of view, the very creation of the virtual replica is highly sensitive and has a significant impact on product performance because you need to create a data transfer system which wasn’t necessary before. Building a realistic replica also requires, on the one hand, powerful modeling technologies and, on the other hand, a fairly cross-disciplinary approach to feed physics and chemistry (for components’ specs and behavior), product engineering, manufacturing operations or in-field environment data

- Once created, the virtual replica must fit somewhere in the existing IT environment: how is it connected to existing ERPs? To what extent is the approach standardized, especially if the company has different DT?

- By centralising access to the virtual replica, DT also raise the question of ownership and decision-making. Who operates the DT? How does it connect to field teams? Who is responsible in the event of a real problem?

Digital Twins combine the best of several technologies into a single solution with a proven ability to generate commercial impact. However, performance varies greatly depending on the company’s digital know-how: because DT work best when deeply integrated into the different stages of the organization – from prototyping to predictive maintenance – its performance and ROI in isolated projects is lower than when it is established at the group level for multiple projects.

2 Key Figures

53 digital twin startups

listed worldwide (created after 2005)

Market size expected to reach $26.1bn by 2025

According to a report carried out by Grand View Research, Inc., the global twin market is projected to be worth $26.07 billion by 2025, registering a CAGR of 38.2% during the period 2019-2025.

3 startups to draw inspiration from

This week, we identified three startups that we can draw inspiration from: Akselos, SightMachine, TWAICE.

Akselos

The Swiss company specializes in Digital Twins for large-scale assets and infrastructure and is already present in 5 locations worldwide.

SightMachine

The US company specializes in upstream digital twins, namely for manufacturing operations, and combines production processes and product data for a better productivity.

TWAICE

The German company empowers electric mobility by providing digital twin technology for batteries. By better predicting the aging and performance of the cells, Twaice improves the reliability of battery systems.