123Fab #66

1 topic, 2 key figures, 3 startups to draw inspiration from

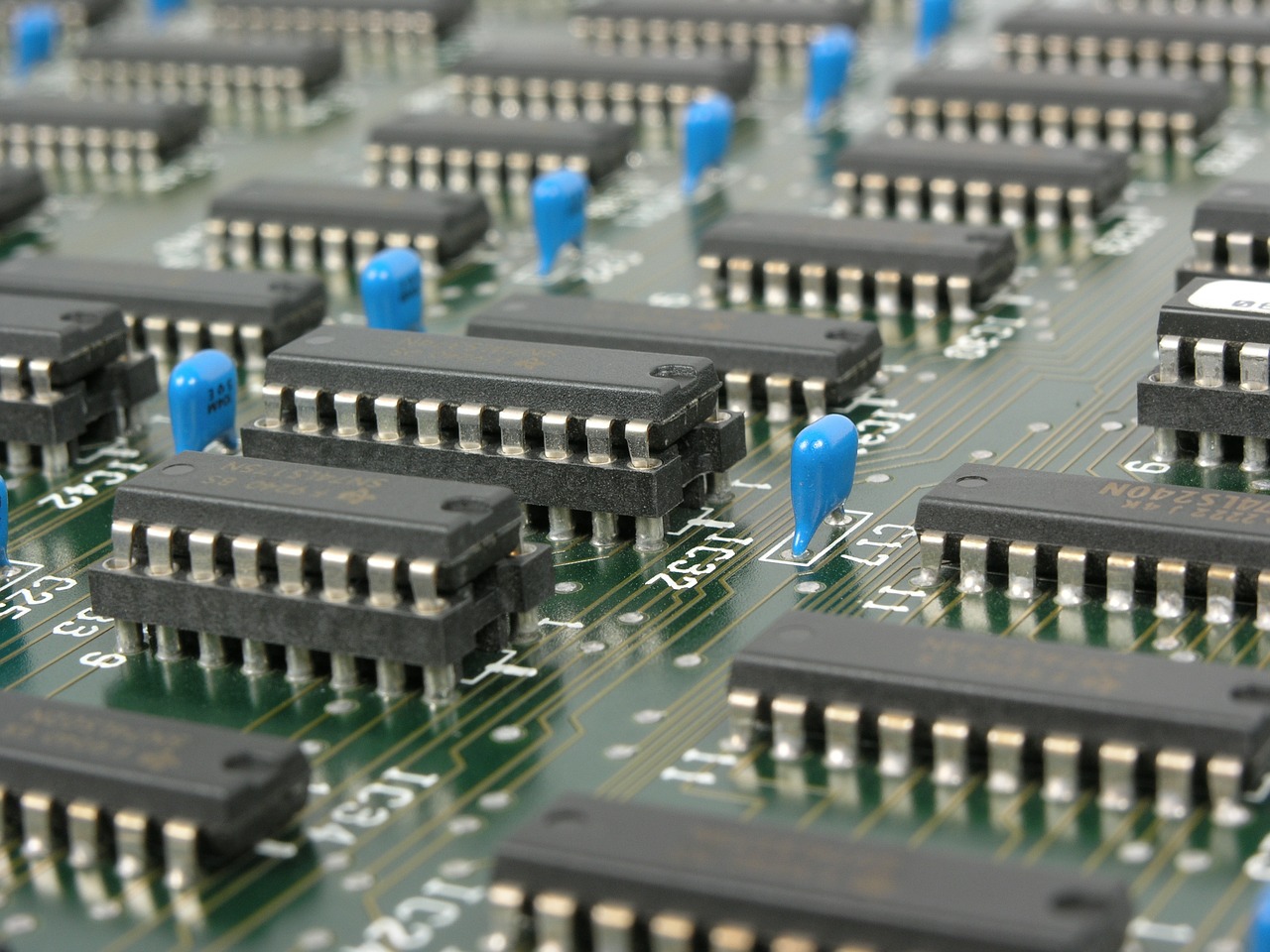

German technology group Bosch announced a few days ago that it would invest more than 400 million euros in microchip production in Germany and Malaysia next year. Similarly, Intel, the largest maker of processor chips for PCs and data centers, said last month that it could invest up to 80 billion euros in Europe over the next decade. These announcements follow the global chip shortage that has plagued the world since the end of the Covid-19 crisis. This shortage is the result of an unforeseen increase in demand, plant closures due to the pandemic, chip stockpiling due to geopolitical tensions, and extreme weather events. It is primarily affecting the consumer electronics and the automotive sectors, with losses that could reach $210 billion according to AlixPartners. Intel and TSMC, two of the world’s largest semiconductor companies, have suggested that the global chip shortage could continue until 2022 or beyond.

Chip is a general term for semiconductor component-based products and is the carrier of integrated circuits, which are divided into wafers. Semiconductors are materials that lie between a conductor and an insulator: they manage and control the flow of current in electronics. They are often made from raw materials such as silicon and germanium, gallium arsenide or silicon carbide. Production is a complex process, taking more than three months and involving giant factories, dust-free rooms, multi-million-dollar machines, molten tin and lasers. To reduce costs, almost all players have specialized in one part of their production chain or in certain types of components.

At a time when chip shortages are hitting many industries, this constraint seems to be ushering the semiconductor industry into a new era of innovation. Big companies are doing what they can to boost production, such as Taiwan Semiconductor Manufacturing Company and Samsung Electronics, for example, which this year achieved the increasingly difficult feat of placing more transistors on each wafer. In May, IBM announced that it had achieved a record level of miniaturization in chip manufacturing (2 nanometers). Recent years have also been marked by the emergence of more and more startups in the semiconductor landscape. While for years venture capitalists considered semiconductor companies too expensive to start, in 2020 they invested more than $12 billion in 407 chip-related companies, according to CB Insights. That is more than double what the industry received in 2019 and eight times the total in 2016. Cerebras, a startup that sells massive artificial intelligence processors that span an entire wafer, for example, has attracted more than $475 million. The firm claims 2.6 trillion transistors in its latest chip, an impressive number compared to the 5.4 billion transistors in the most powerful conventional processor. In April, SambaNova raised $676 million for its reconfigurable artificial intelligence chips. This growth may be related to the need to design new chips capable of running increasingly complex artificial intelligence models, especially for neural networks and convolution.

Beyond chip production and manufacturing, startups are trying to tackle the complexity of semiconductor creation by improving planning and productivity in fabs. Startup Flexciton has created software based on mixed integer linear programming for better factory scheduling. This reduces the time it takes the plant to produce each semiconductor by 7-10%, which would translate into savings of $3-5 million per month. The startup raised £15 million in August. Motivo, a five-year-old startup, is creating software to speed up chip design using AI. The product examines, among other things, the layout of the chip, the underlying RTL code that makes the chip work and the netlist. The company’s ultimate goal is to cut the chip design process from three years to three months. In August, the company announced a $12 million Series A round.

The current chip shortage is causing quite a stir and is pushing companies of all sizes to innovate in order to increase production and meet the growing demand. States are also mobilizing for their sovereignty: South Korea announced a push worth $450-billion over ten years, the United States is pushing legislation worth $52 billion, and the EU could plow up to $160-billion into its semiconductor sector. The current situation reveals our dependence on these critical resources and also shows us what is in store for us in the next 30 years. Indeed, the exploitable resources of certain rare metals, which are essential for the production of chips, could be exhausted within a few decades. Other threats to the sector include climate change. In Taiwan, the world’s number one chipmaker, TSMC, which alone uses 156,000 tons of water per day, had to innovate to cope with the historic drought last spring. Minimizing waste and making progress on chip recycling will be crucial for the future.

2 Key Figures

The global semiconductor market is expected to reach $778 billion by 2026 with a CAGR of 7.7% from 2021 to 2026

Reportlinker

+400 semiconductor startups

Crunchbase – 2021

3 startups to draw inspiration from

This week, we identified three startups that we can draw inspiration from: Untether IA, Flexciton and Motivo.

Untether AI

The startup is specialized in the production of AI acceleration chips for data centers, network edge equipment and embedded systems. It combines the eco-efficiency of near-memory computing and the robustness of digital processing for neural network inference. Intel has participated in the financing of the startup.

Flexciton

The startup has developed a solution to improve the efficiency and productivity of fab manufacturing processes. Using AI-powered mathematical algorithms and Mixed Integer Linear Programming, the solution analyse real-time data to make the best choices possible and decide which actions need to be taken to optimise production.

Motivo

The startup has developed a platform to to accelerate chip design utilizing a learning-on-graph methodology for automated data-driven feature extraction. This enables the platform to recognize and find patterns in the layout and make millions of improvements automatically and in an intelligent way all within the design rules.

Interested in a startup landscape or in an insights report?

Please fill out our contact form so that we can get back to you very quickly with our product offer.

Want to subscribe to our 123Fab?

Fill out our form to receive the latest insights into your inbox.